• Design and development of fuel handling system for AHWR

• Providing engineering support for design of fuel handling systems for PHWRs.

• Development of tools for life management of PHWR coolant channels.

• R&D in tribology.

• FE analysis & evaluation of mechanical properties at high strain-rate loading conditions.

• Development of Fluid Power Technology.

• Qualification of shipping casks.

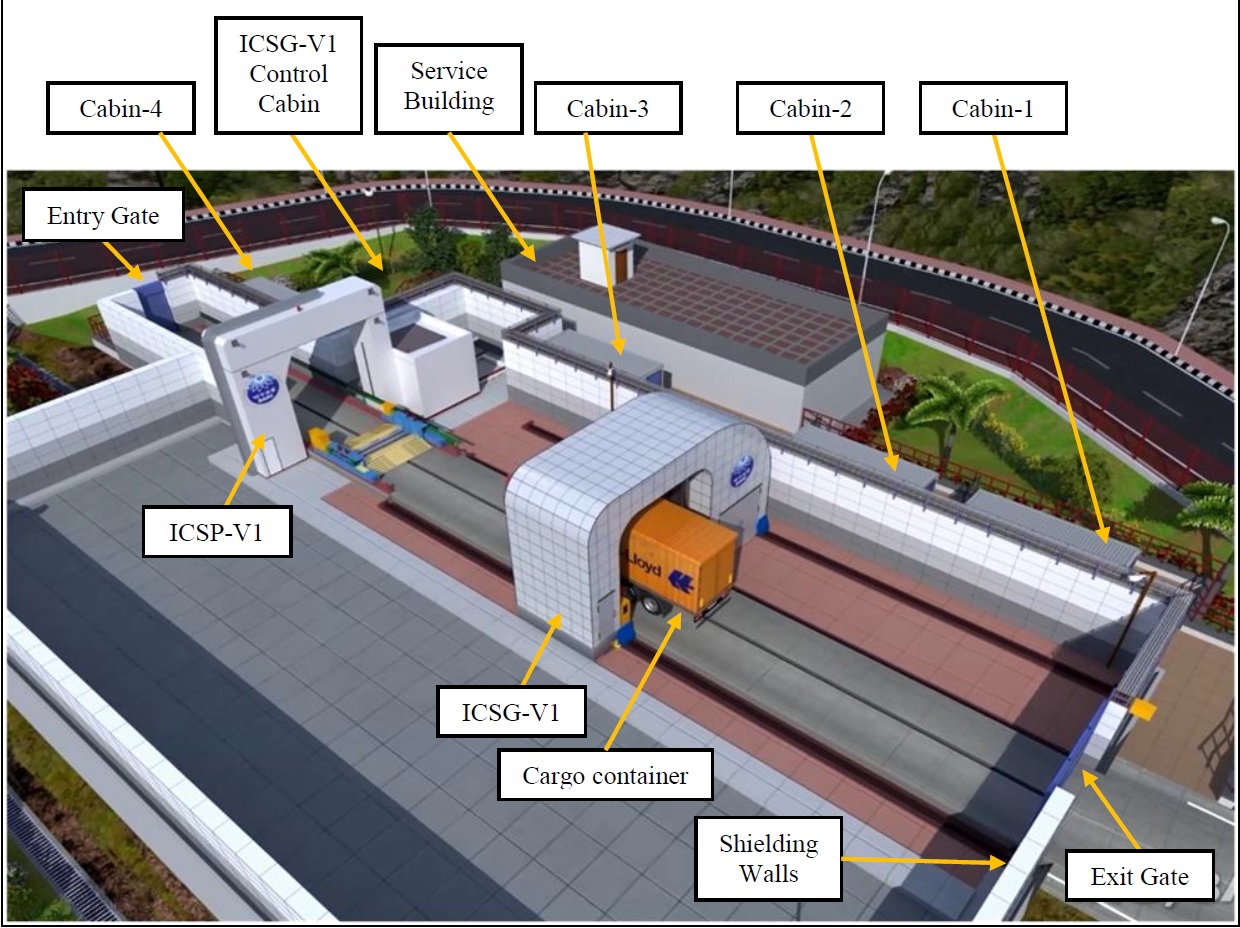

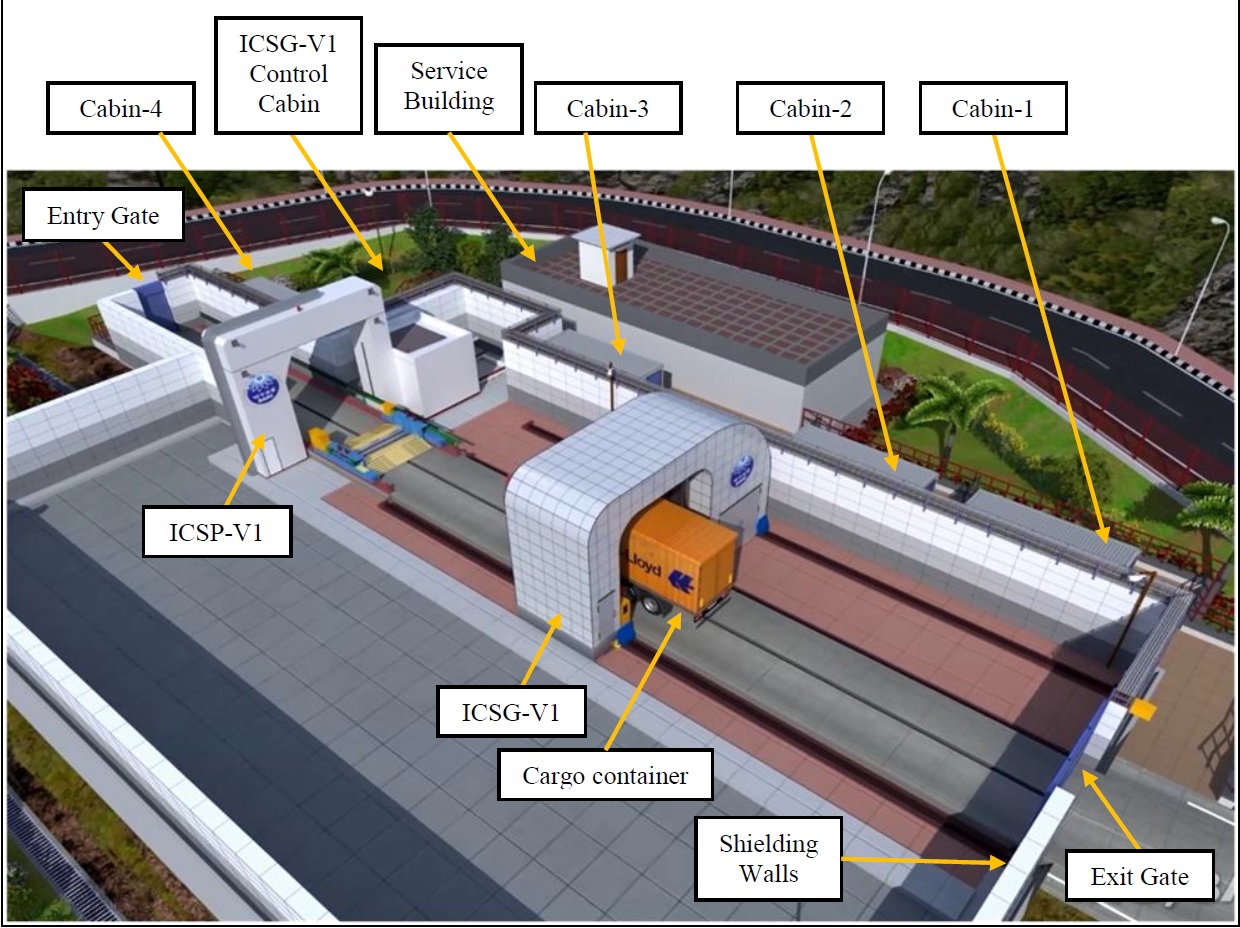

• Operation, maintenance and experiments in Indian Cargo Scanner facility at Gamma field, BARC

• Operation, maintenance and upgradation of Integral Thermal Facility (ITF)

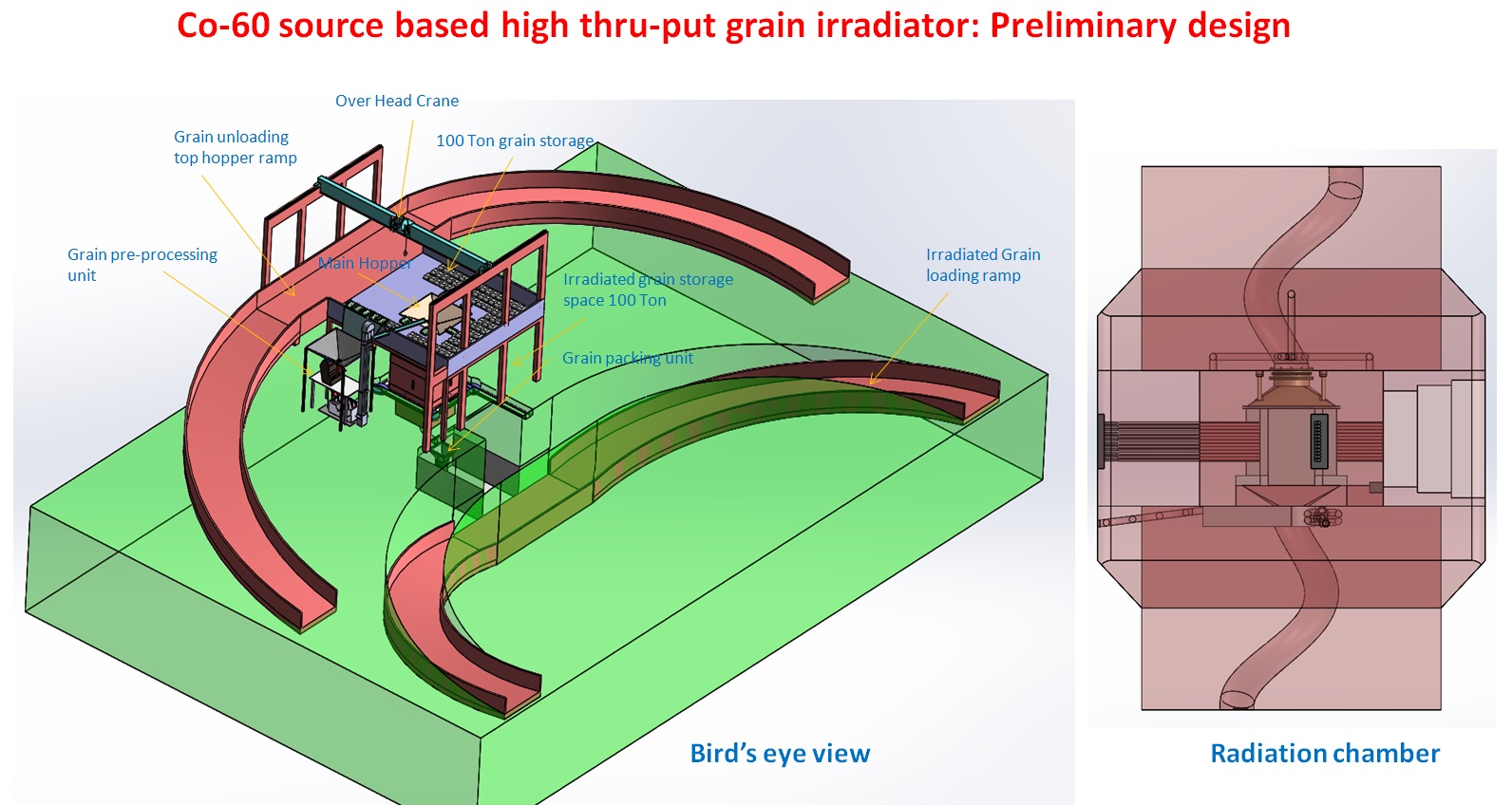

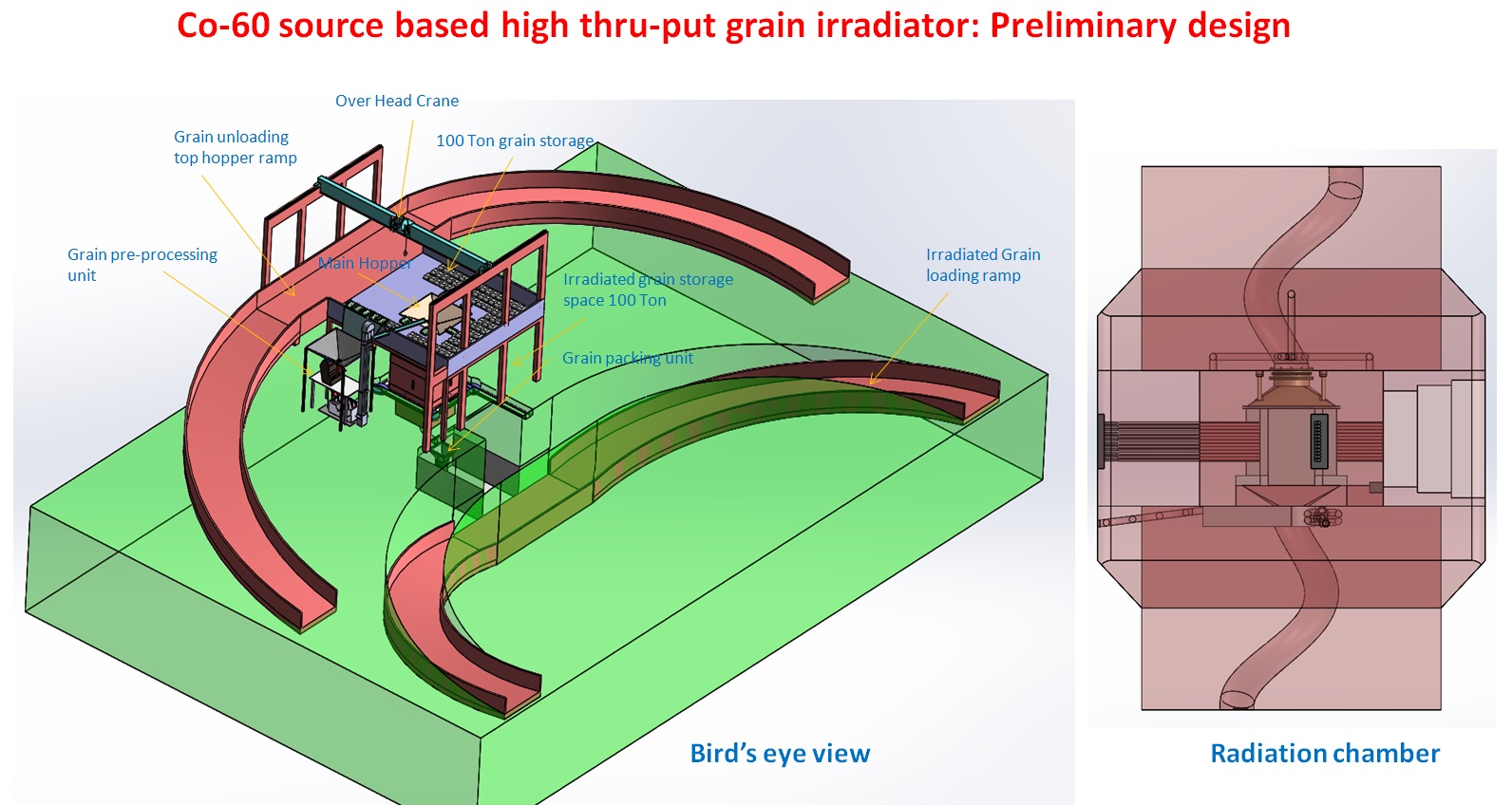

• Design & development of Co-60 based high throughput grain irradiator.

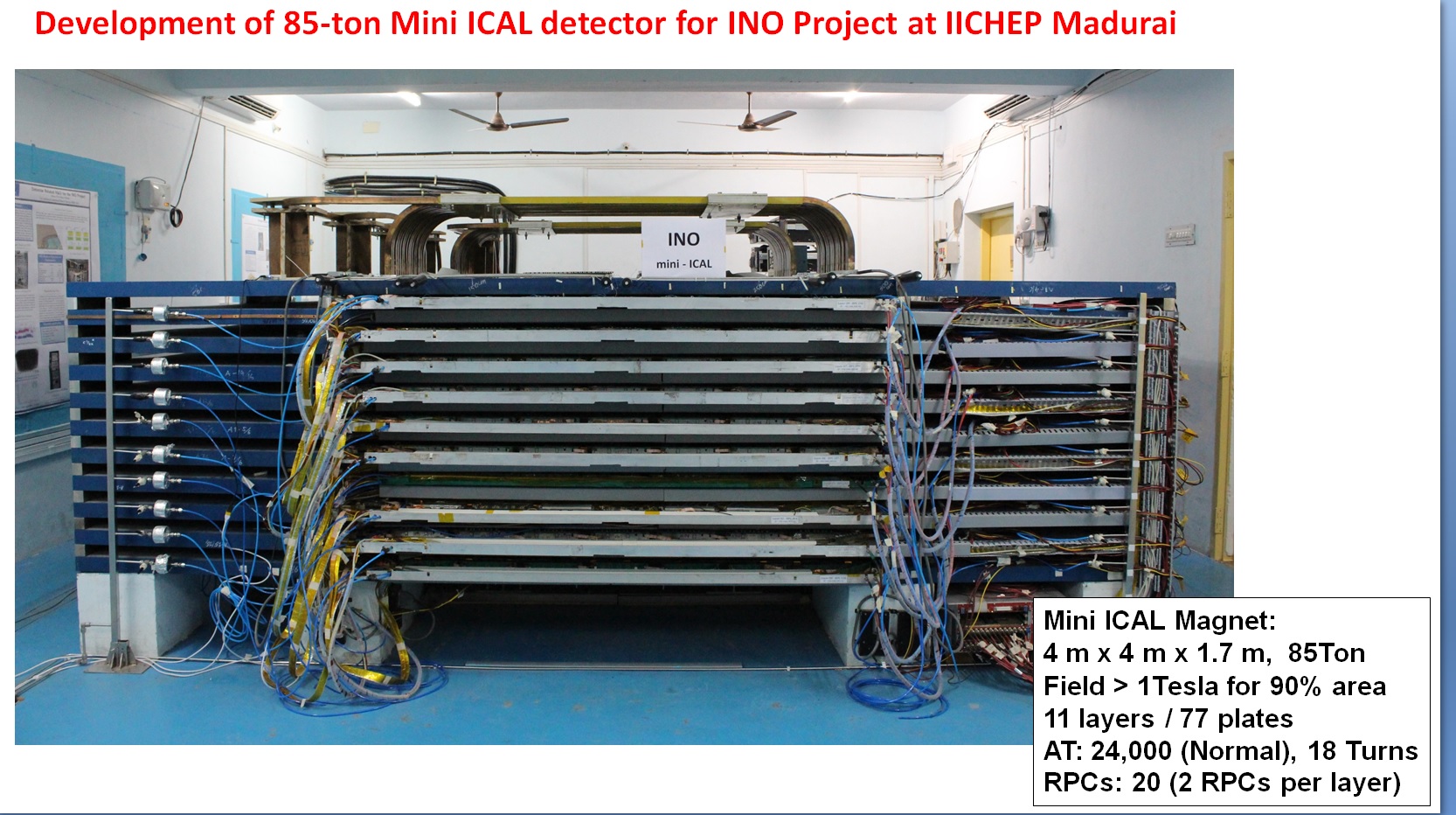

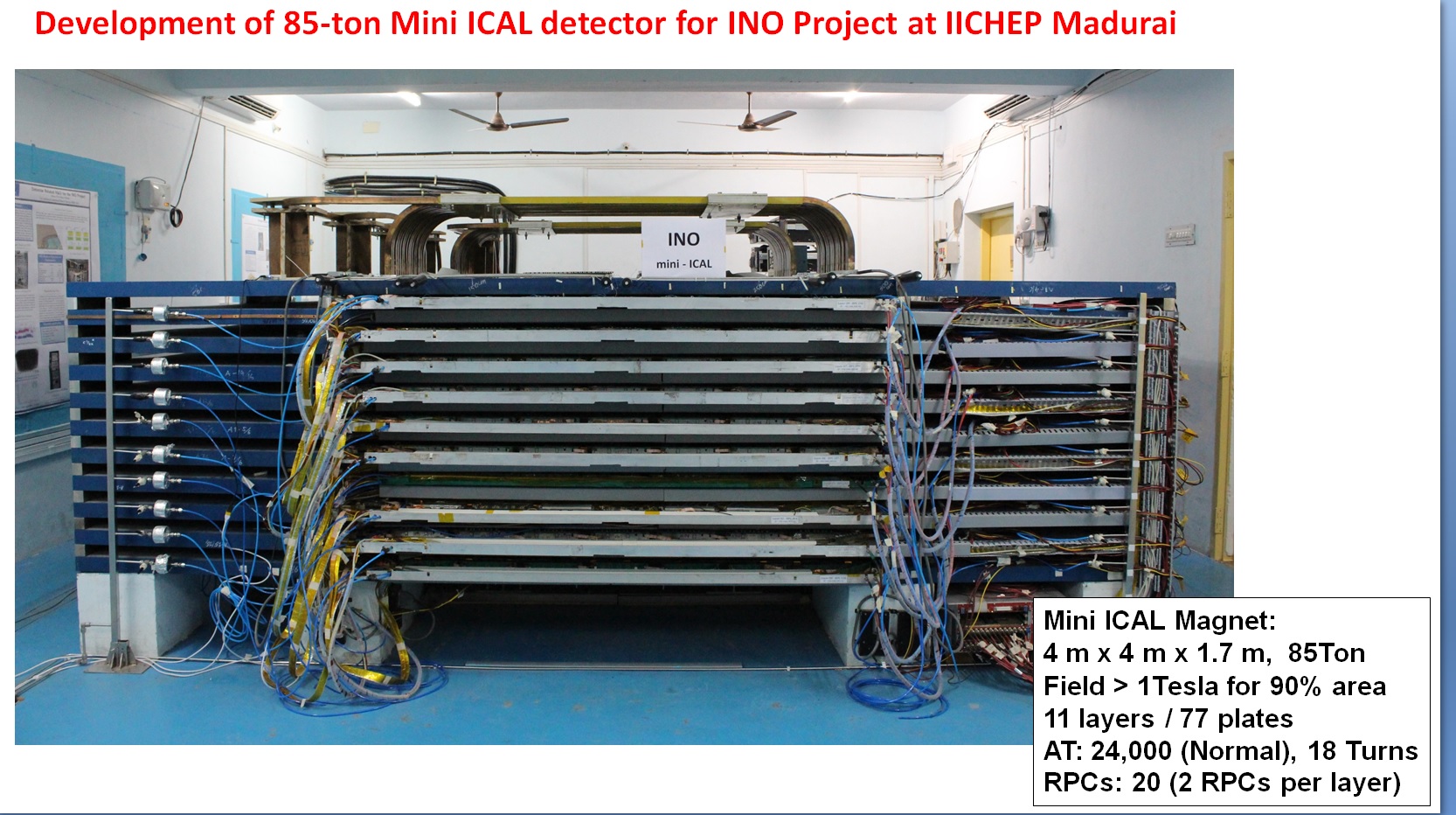

• Design & development of special equipment for ICAL magnet of INO project.

• Design & development of components for E-ICAL magnet

• Design & development of Mini ICAL magnet at Madurai, TN.

TMAC (Technique for Measurement of Axial Creep) version 4.0 was developed

\r\nto measure axial creep in the coolant channels of PHWRs. TMAC version 4.0

\r\nconsists of a data acquisition card (hardware), software, and an operation

\r\nmanual. The new version is designed for 220 and 700 MWe PHWRs. This newly

\r\ndeveloped TMAC was successfully deployed at the KAPS-4 unit in December

\r\n2023.

1/2022

1/2022

1/2022

1/2022This grain irradiator will disinfest food grains to store for a longer period and to provide clean and hygienic food grains to consumers. It will address problem of food wastages at various stages of food chain.

1/2021

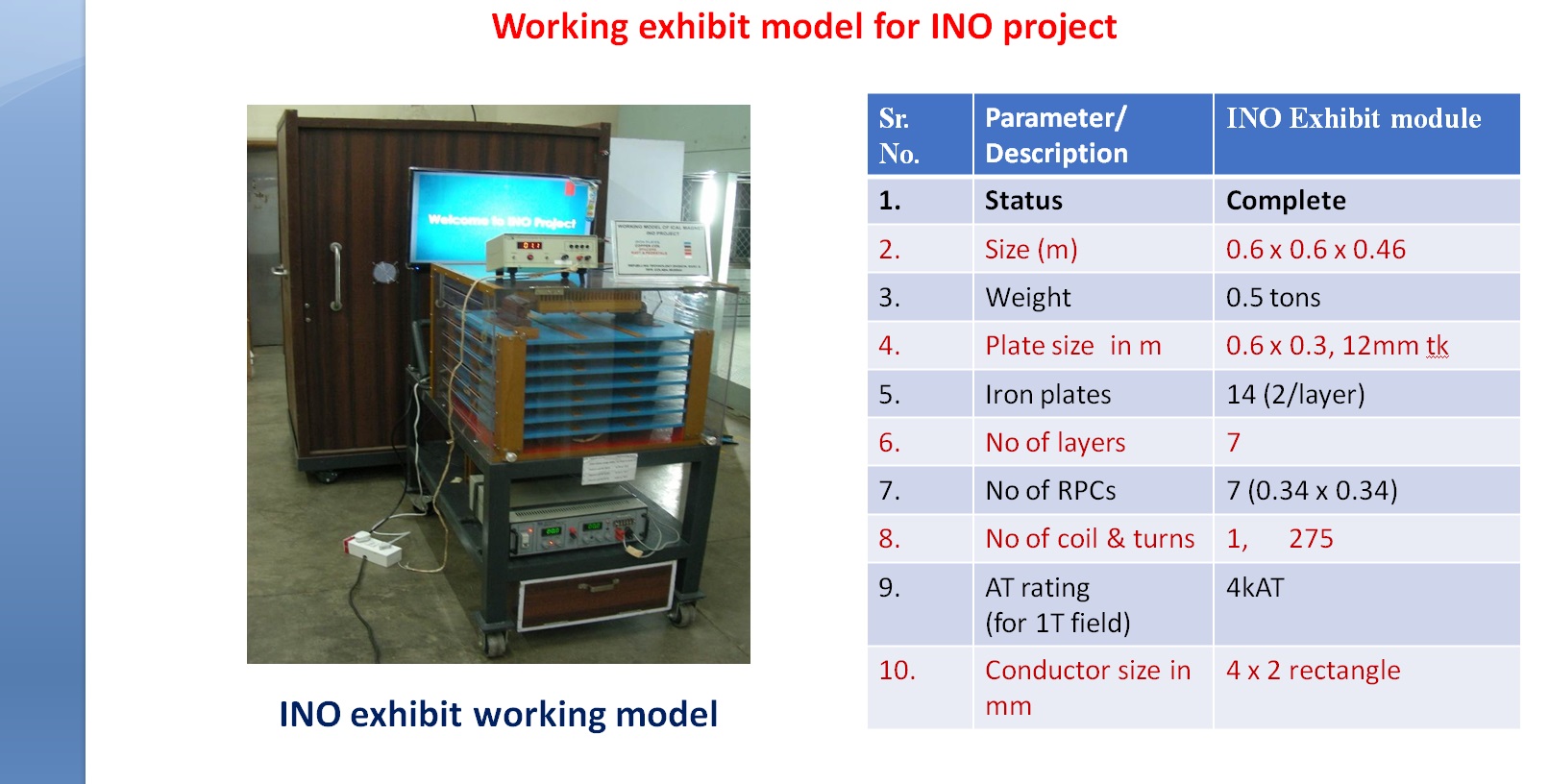

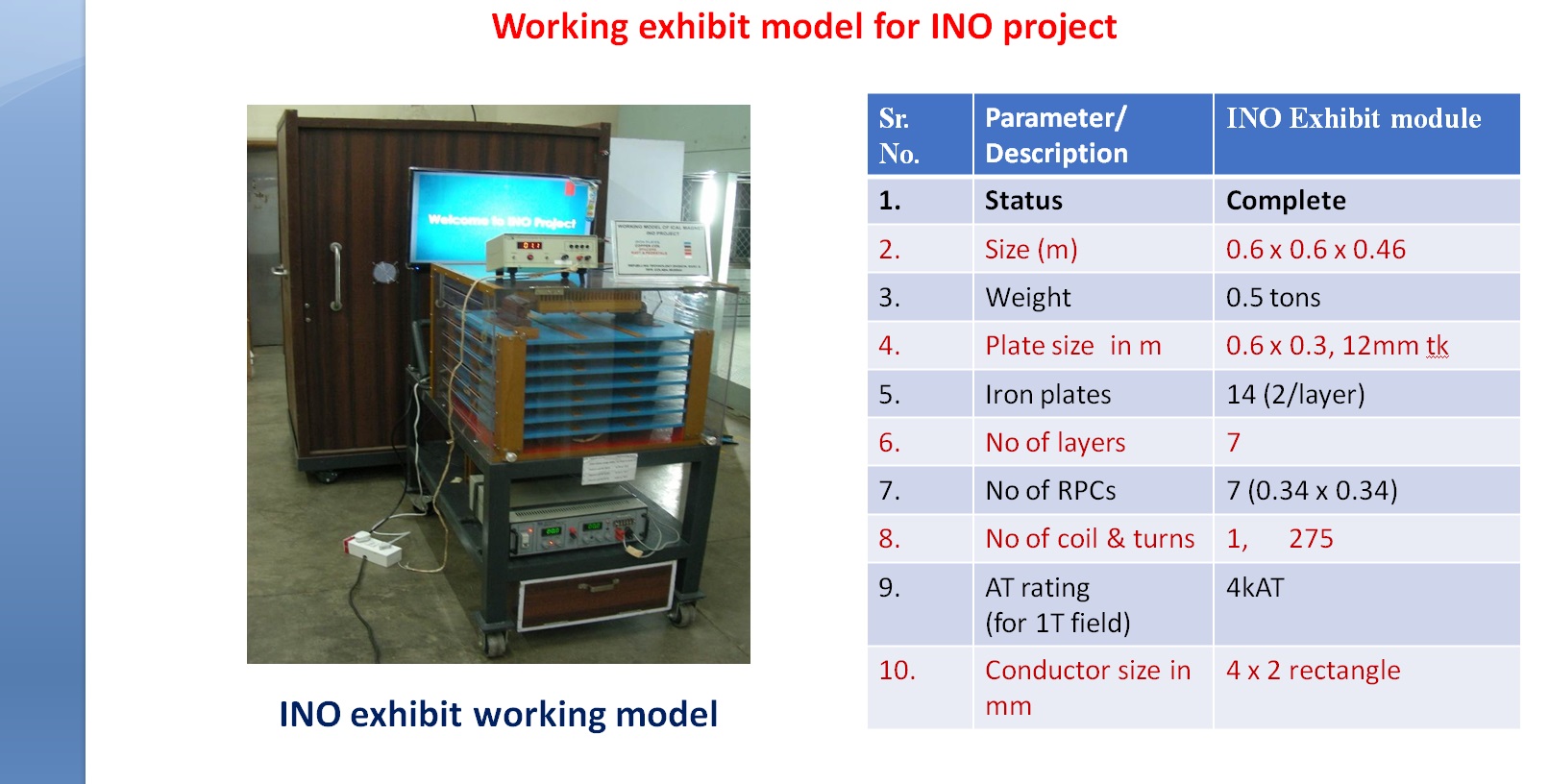

1/2021A scaledown version of ICAl magnet with 7 soft iron layers of 600mm x 600mm size with suitable RPC tray detector has been built for demonstration during science exhibitions and outreach programs.

Objective of this facility is to process food grain using radiation for disinfestation and utilization of cs-137 for societal application.

Objective of this facility is to process food grain using radiation for disinfestation and utilization of cs-137 for societal application.

Objective of rod cutting gadget is to cut damaged fuel rods and insert into the bucket inside the cut rode storage bay of CIRUS as decommissioning activity

Objective of rod cutting gadget is to cut damaged fuel rods and insert into the bucket inside the cut rode storage bay of CIRUS as decommissioning activity

Flight Motion Simulator (FMS) is a three axis table required for simulated performance evaluation of inertial sensor based equipment, Radar Seekers etc. This was manufactured in collaboration with RCnD and ECIL.

In HFRR, Irradiation assemblies need to be transferred from service pool to upper hot cells and spent fuel assemblies need to be transferred from service pool to lower hot cell via upper hot cell. Therefore, spent fuel and irradiation assembly transfer system was needed to be developed. Design of this SIATS has been completed.

In HFRR, Irradiation assemblies need to be transferred from service pool to upper hot cells and spent fuel assemblies need to be transferred from service pool to lower hot cell via upper hot cell. Therefore, spent fuel and irradiation assembly transfer system was needed to be developed. Design of this SIATS has been completed.

Seismic Switch technology was developed indigenously and transferred to ECIL. Product developed on transferred technology was commissioned at KAPPS 3&4

Seal & shield plug assembly and extractor assembly was needed to be developed for allowing on power refuelling of DHRUVA, as part of safety upgradation of fuelling machine. These components were developed and delivered to DHRUVA

1/2020

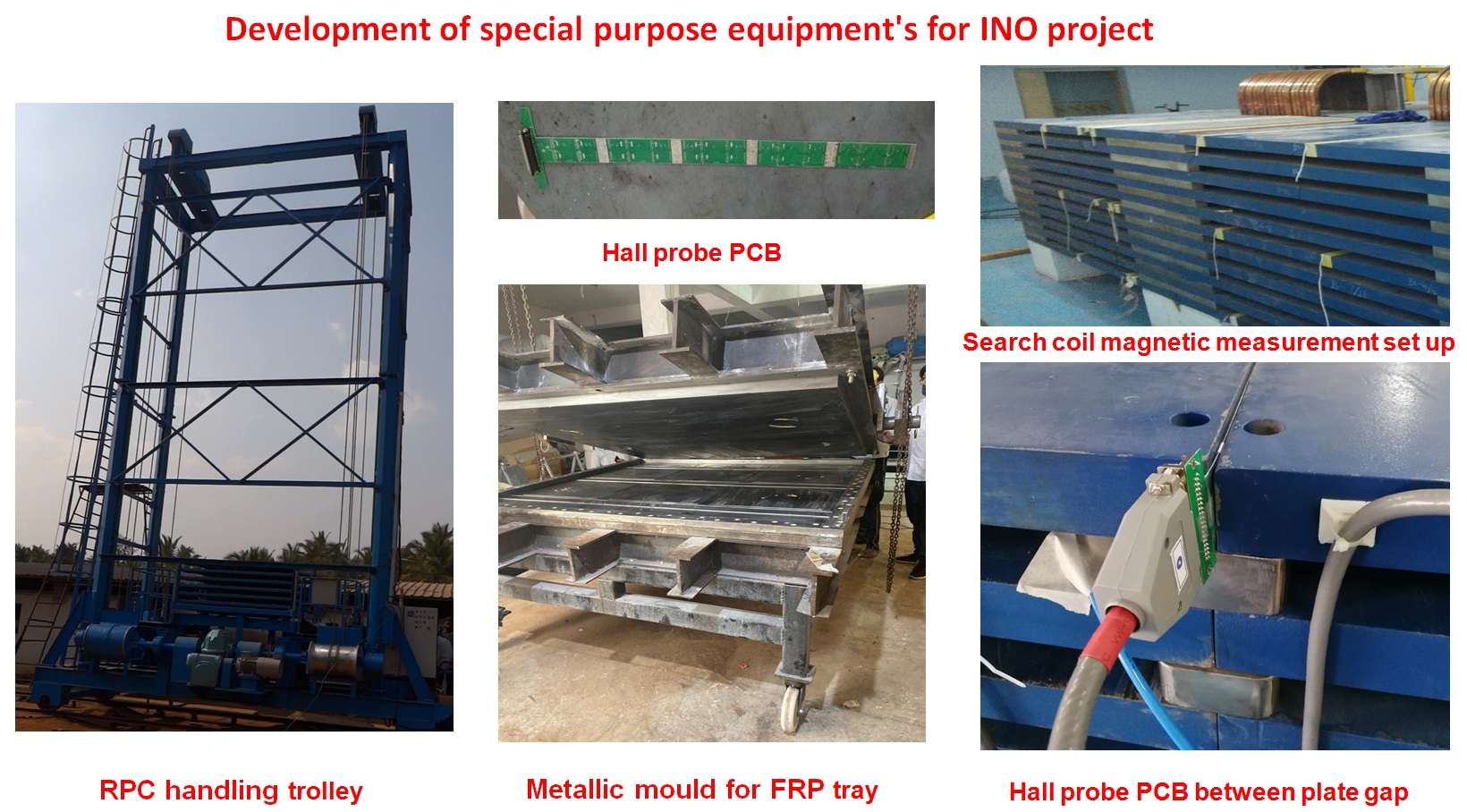

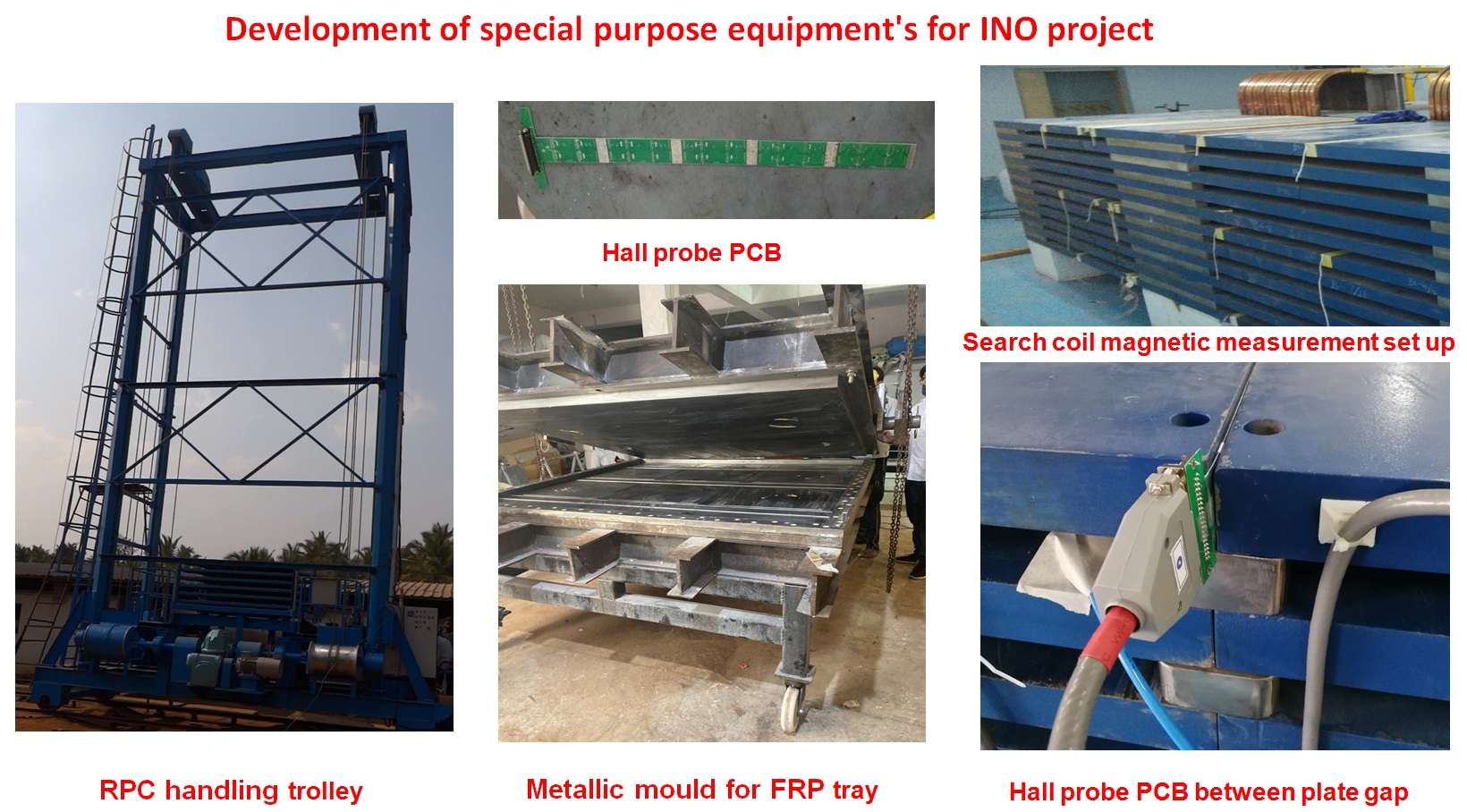

1/2020Completed special purpose equipment are gap measurement system, magnetic field measurement system, RPC handling trolley, Gantry carne, Brazing machine, metallic mould for FRP tray for RPC.

High Flow Control Valve is indigenous water hydraulic valve developed for controlling the flow of high pressure water irrespective of variation in pump pressure and load pressure. This valve was developed and tested at RTD, BARC.

1/2019

1/2019An engineering prototype -E-ICAL is being developed. Components like copper coil, procurement of soft iron plates, machining of spacers & pin assembly, G-10 material coil insulating brackets has been completed.

1/2019

1/2019Description: A 85 ton 4m x 4mx1.8m Mini ICAL magnet has been built at IICHEP Madurai TN. The objective of this magnet is to establish design of magnet components, associated systems and to provide test facility for testing RPC detectors. Mini ICAL is operational since its installation.

Waste water treatment setup was developed and waste water treatment was demonstrated using electron beam accelerator at EBC, kharghar.

Fuel bundle handling & tray handling tool was developed to remotely handle fuel bundles and tray in Spent Fuel Storage Bay. it leads to reduction in man-rem consumption.

Fuel bundle handling & tray handling tool was developed to remotely handle fuel bundles and tray in Spent Fuel Storage Bay. it leads to reduction in man-rem consumption.

KAMINI reactor has been refurbished in terms of control and instrumentation. Since Safety Control Plate (SCP) drive mechanisms have seen life of more than 20 years, it was felt that new SCP drive mechanisms need to be installed on the reactor. The SCP drive mechanisms were modified with latest features and newly fabricated mechanisms were tested and installed on the reactor.

SHPB is an inhouse developed experimental test setup that is used to evaluate material property at high strain rate loading. This setup is used to carry out compression and tensile tests in strain rate range of 102 to 104 s-1.

500kg payload Shake Table and its associated control system was developed indigenously by RTD, provides facility to conduct various experiments on Structures, Systems and Components.

3/2016

3/2016Fuelling Machine Test Facility (FMTF) is being established at R&D Tarapur for testing of full scale prototype Fuelling Machine (FM) in reactor simulated condition to validate the design. Machine is installed on test bed and its commissioning is in progress

For quantitative analysis of water and oil, the Fluid Power lab has particle counting machines which can count particles and report its cleanliness in NAS & ISO standards.

Ferrography is wear particle analysis technique used for oil wetted parts of machine. The particles in the lubricating oil carry detailed information about the condition of machine. This may be deduced from particle size, shape, composition and concentration. Ferrography uses a high gradient magnetic field to attract and hold particles from fluid sample which flows down a microscopic slide inclined at a small angle to horizontal.Significant information about the composition of wear particles may be obtained by heat treating ferrograms and observing the change in appearance of the particles. Ferrous alloy particles may be categorized into broad alloy classes by the temper colors formed by heating.

A damper test facility was developed in house to conduct dynamic testing on hydraulic dampers.Hydraulic dampers have variable orifices to control the damping and operated by solenoid valves controlled via micro controller. The test facility has an electric linear actuator and a servo motor with gear box to cause linear and angular controlled motions on the hydraulic damper.Dampers are passive in nature and can cause controlled deceleration during extension and retraction of damper.

All the components of the 6 DOF 5Te Servo Hydraulic Shake Table facility has been truly designed and developed inhouse. This involved Multidisciplinary approach in Hydraulic systems, Control techniques, Mechanical engineering, Computer, Electronics and Mathematics.This is an Eight actuator parallel manipulator with Fluid power as Motive force.This facility can be used to generate earthquake ground motion to study their effects on nuclear piping, reactor components, buildings.All Existing 6DOF servo hydraulic shake tables in India are imported.

A job specific induction brazing machine has been developed for in-situ brazing of upper and lower portions of copper coil for ICAL magnet.

This facility is indigenously developed to test structures, components and equipments upto 500 kg.

Fuelling Machine Testing Facility, Hall-7

Tribology Lab consists of following facilities

\r\n1. Cavitation Erosion Test Facility.

\r\n2. Linear Reciprocating Tribometer.

\r\n3. Pin on disc test setup.

\r\n4. Stereo Microscope.

fluid power lab was developed to provide training for different fluid power related technologies

Assembly of FM, installation of equipment, Hydraulic system, control design, operating procedures, safety review and maintenance of FMTF, Tarapur

• For rector simulated temperature and pressure condition with 2 nos pumps capable of suppling 25 kg/s flow (max. for 540 MWe)

\r\n• 1.2 MW heaters, 5200 A ,100 V, 19 mΩ each

\r\n• 2 nos of 220 MWe channels – full length

\r\n• 540 MWe channel – full length

\r\n• One newly installed 540 MWe channel for channel components dynamics

\r\n• 540 MWe FM with control room, water and oil hydraulic system

\r\n

31-05-2024

31-05-2024This software performs offline data analysis of huge amount of data in time domain and frequency domain and generate reports, Fig. data analysis soft.jpg.

31-05-2024

31-05-2024User-friendly software for indigenous 5Te 6DOF shake table was developed which generates spectrum compatible acceleration time histories in three axes using Fast Fourier Transform and Duhamel methods to be fed to seismic shake table.The acceleration and displacement time time history is shown in Fig. Seismic testing software.jpg. If the displacement exceeds the shake table limits, then low frequency content is removed to meet the limits of shake table.

\r\nAfter seismic testing, test report with superimposed test response spectrums is generated by software, Fig. test report.jpg.

31-05-2024

31-05-2024User-friendly software for indigenous 5Te 6DOF shake table was developed which generates spectrum compatible acceleration time histories in three axes using Fast Fourier Transform and Duhamel methods to be fed to seismic shake table.The acceleration and displacement time time history is shown in Fig. Seismic testing software.jpg. If the displacement exceeds the shake table limits, then low frequency content is removed to meet the limits of shake table.

\r\nAfter seismic testing, test report with superimposed test response spectrums is generated by software, Fig. test report.jpg.

A DC B-H loop tracer has be made as per IEC60404-4 standard for testing of various magnetic material used for different applications in BARC.The equipment utilizes the method accepted by ASTM.A loop tracer has facility of testing rod type sample & ring type sample. Maximum capacity is 500 Oe with rod type sample and 150 Oe with ring type sample.

This is functional exhibit model representing INO project. This 0.5-tonmodel contains, 7 soft iron layerswith 7 RPC detector, inbuilt power supply, magnetic measurement set up and video display. Model is being used during science exhibitions and outreach programs.

This software has extensive use for design & development of electromagnetic components.

A methodology to determine fracture properties under high strain rate loading is developed using the modified SHPB.

Given the operating pressure, speed, force, and stroke, the complete design of all the component so of actuator are calculated and a report is generated with part dimensions.

Analog and Digital Seismic Switch technology was indigenously developed and transferred to ECIL. Products also installed at KAPPS 3&4.