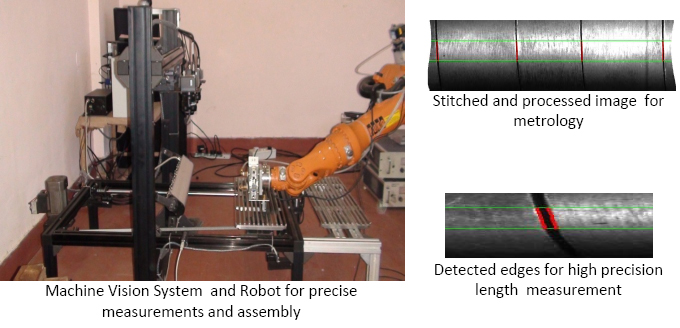

Modern technologies like machine vision and robotic automation are fast coming together to push manufacturing automation to higher reliability and precision. Under automation program of Department of Atomic Energy, Bhabha Atomic Research Centre has developed a vision based robotic system that enables measurement and assembly of components with accuracy up to 100 micron. In this system, objects are carried along a conveyor into a vision station. Here, images of the top surface are captured by a pair of high resolution line scan cameras and used for accurate length measurement. Thereafter, intelligent algorithm guides an industrial robot to rearrange components so as to meet tolerance of ± 1 mm for the final assembly.

With the increasing demand for high quality assurance, manufacturers have to ensure that production lines employ the latest in measurement and manufacturing technology. Very often, it is challenging to maintain tight tolerance of components produced through compaction, extrusion and other gross manufacturing techniques. It is then required to pick components intelligently and stack them together for attaining desired length of final assembly.

In order to perform these intricate operations, BARC has developed a vision based robotic system that enables measurement of component lengths with accuracy up to 100 micron. To do so, components are carried along a conveyor into vision station. In the station, images of the top surface are captured by a pair of high resolution line scan cameras and used for accurate length measurement. Thereafter, intelligent algorithm guides the industrial robot to rearrange components so as to meet tolerance of ± 1 mm for the final assembly.

With the increasing demand for high quality assurance, manufacturers have to ensure that production lines employ the latest in measurement and manufacturing technology. Very often, it is challenging to maintain tight tolerance of components produced through compaction, extrusion and other gross manufacturing techniques. It is then required to pick components intelligently and stack them together for attaining desired length of final assembly.

In order to perform these intricate operations, BARC has developed a vision based robotic system that enables measurement of component lengths with accuracy up to 100 micron. To do so, components are carried along a conveyor into vision station. In the station, images of the top surface are captured by a pair of high resolution line scan cameras and used for accurate length measurement. Thereafter, intelligent algorithm guides the industrial robot to rearrange components so as to meet tolerance of ± 1 mm for the final assembly.

Skilled manpower is required for following activities: