Pb-Li alloys are very important alloys for fusion technology. However, diverse physical properties of lead and lithium elements pose severe restrictions in the synthesis of lead-lithium alloys which make the production of these alloys technically a very challenging task. Materials Group has developed an innovative fused salt method based technology for the production of Pb-Li alloy. Currently the production was demonstrated in batches of 20 kg, but it can easily be scaled up to any desirable batch size. This technology does not involve handling of highly pyrophoric metallic lithium. In place it uses very cheap substitute in form of salt mixture of lithium-chloride and potassium-chloride. This salt mixture is used to produce lithium ions in a semi-automated fused salt electrolysis inconel reactor which contains electrically-insulating ports for cathode insertion, gas inlet/outlet and a specially made inconel cage with a hydraulic-lifting mechanism. Li ions produced by the electrolysis-process were allowed to diffuse directly into the liquid lead in a control way to suppress the formation of undesirable phases without any fire hazard. Many such innovative steps ensured uniform distribution of lithium atoms in the alloy. Robustness and reproducibility of the technology was successfully tested several times.

Pb-Li alloys are very important alloys for fusion technology. However, diverse physical properties of lead and lithium elements pose severe restrictions in the synthesis of lead-lithium alloys which make the production of these alloys technically a very challenging task. Materials Group has developed an innovative fused salt method based technology for the production of Pb-Li alloy. Currently the production was demonstrated in batches of 20 kg, but it can easily be scaled up to any desirable batch size. This technology does not involve handling of highly pyrophoric metallic lithium. In place it uses very cheap substitute in form of salt mixture of lithium-chloride and potassium-chloride. This salt mixture is used to produce lithium ions in a semi-automated fused salt electrolysis inconel reactor which contains electrically-insulating ports for cathode insertion, gas inlet/outlet and a specially made inconel cage with a hydraulic-lifting mechanism. Li ions produced by the electrolysis-process were allowed to diffuse directly into the liquid lead in a control way to suppress the formation of undesirable phases without any fire hazard. Many such innovative steps ensured uniform distribution of lithium atoms in the alloy. Robustness and reproducibility of the technology was successfully tested several times.

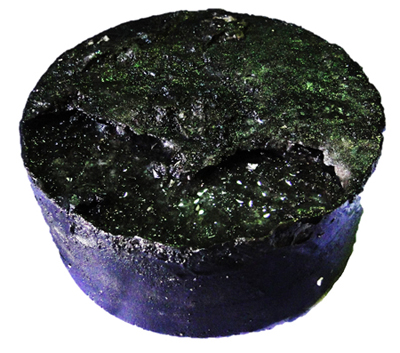

Dilute Pb (0.2 wt% to 1.1 wt %)- Li alloys in the batch of 20 kg scale, without using highly pyrophoric lithium metal, can be produced without involving very high technically qualified person.

Pb-Li alloys are very important alloys for fusion technology. However, diverse physical properties of lead and lithium elements pose severe restrictions in the synthesis of lead-lithium alloys which make the production of these alloys technically a very challenging task. Materials Group has developed an innovative fused salt method based technology for the production of Pb-Li alloy. Currently the production was demonstrated in batches of 20 kg, but it can easily be scaled up to any desirable batch size. This technology does not involve handling of highly pyrophoric metallic lithium. In place it uses very cheap substitute in form of salt mixture of lithium-chloride and potassium-chloride. This salt mixture is used to produce lithium ions in a semi-automated fused salt electrolysis inconel reactor which contains electrically-insulating ports for cathode insertion, gas inlet/outlet and a specially made inconel cage with a hydraulic-lifting mechanism. Li ions produced by the electrolysis-process were allowed to diffuse directly into the liquid lead in a control way to suppress the formation of undesirable phases without any fire hazard. Many such innovative steps ensured uniform distribution of lithium atoms in the alloy. Robustness and reproducibility of the technology was successfully tested several times.

Currently the production was demonstrated in batches of 20 kg, but it can easily be scaled up to any desirable batch size.

Dilute Pb (0.2 wt% to 1.1 wt %)- Li alloys in the batch of 20 kg scale, without using highly pyrophoric lithium metal, can be produced without involving very high technically qualified person.

The details of the facilities are mentioned below:

Capital items required and their specifications

Consumables required