Alkali Material and Metal Division (AMMD) of Bhabha Atomic Research Centre is extensively involved in development and deployment of various advanced technologies for the Department as well as Industry. The present technology describes a respirator device which has twin cartridge setup to resist mercury, E-1 type acid vapors and particulates. This configuration/device can be effective for removal of mercury vapors, acid vapors and dust particles from contaminated air.

Use of respiratory protective equipment for health protection is the last but crucial line of defense against toxic air borne containments. Many industrial operations give rises to air borne contaminants in low concentration which causes various health issues more often than pose a serious threat to life and health. Respiratory protection is desirable in such situations. It is essential that the respiratory protection device be suitably tested in the laboratory under simulated condition and the defects, if any, removed so that desired protection is afforded during the actual use. Most of the respiratory cartridges use carbon-based adsorbent that generates lots of secondary waste. There are very limited manufacturers in India who are providing mercury respiratory cartridges and to the best of our knowledge none of them uses carbon-free adsorbent. The newly developed multi-contaminant exposure resistant cartridge features a highly effective filtration system, utilizing modified zeolite as an adsorbent material. This advanced design not only targets the removal of mercury and acid vapors but also introduces the potential for reusability through regeneration (if required). This document discusses the design, functionality, and testing of the cartridge, alongside its compliance with regulatory standards (NIOSH and IS), and the benefits of using non-carbon is enhanced reusability. These in-house synthesized cartridges are unique in the sense that the raw material used is easily available, environment friendly, generate lesser secondary waste and may be reused after proper procedure. It provides efficient protection against mercury & acid vapors exposure as well as particulate contaminants. It meets both NIOSH and Indian Standards (IS) for occupational safety and performance. It ensures reliable, long-term use without compromising worker health or comfort. It is primarily meant for environments where there is a risk of mercury and/or acid vapor exposure and/or particulate contamination, such as: Industrial Settings, Electronics manufacturing, Laboratories, Mining Operations, Environmental Cleanup, Healthcare Facilities, Waste Management etc. These are Eco-friendly and User-friendly. It generates no carbon, has low pressure drop compared to existing cartridges. The adsorption performance is verified with IS standard, having Shelf life of 2 years (minimum). The constituents are easily available locally. Easy synthesis route, simple setup, no complex infrastructure and with several application possibilities are the additional benefits.

Alkali Material and Metal Division (AMMD) of Bhabha Atomic Research Centre is extensively involved in development and deployment of various advanced technologies for the Department as well as Industry. The present technology describes a respirator device which has twin cartridge setup to resist mercury, E-1 type acid vapors and particulates. This configuration/device can be effective for removal of mercury vapors, acid vapors and dust particles from contaminated air.

This product is a respiratory cartridge with particulate filter fitted in to a proven respirator to resist mercury vapor, acid vapors (E1 type) and particulate exposure from contaminated air using a carbon free adsorbent and P-3 type particulate filter. This product has been designed as per IS15323:2003 standard, and has been tested and qualified by a BIS certified laboratory for its performance. This leaflet will explain selection and preparation of adsorbent, its characterization, reusability studies, cartridge sizing, particulate filter selection, testing and approval procedure as per BIS and follows NIOSH Procedure No. RCT-APR-STP-0044 Revision 1.1 & NPPTL-APR-STP-0048-508 for mercury and acid vapor, respectively. A suggestive design consideration towards product development has also been provided considering a prototype, which may change taking into account various modalities including scale of application of end-user and field conditions.

Mercury Respiratory Cartridges: Mercury is a toxic metal that can be inhaled as vapor, especially in industrial processes such as the manufacture of fluorescent lights, thermometers, or in the mining of gold (where mercury vapor is often released). Mercury vapors are extremely hazardous, and special cartridges designed to filter out these vapors are used.

Areas of Application:Acid Vapors Respiratory Cartridges: E-1 class acid vapors, such as those from sulfuric acid, hydrochloric acid, and nitric acid etc.

Areas of Application::Particulate Filters: Particulate filters are designed to remove solid particles, such as dust, smoke, and fumes, from the air. These filters are often made from fibrous materials and are classified based on the size of the particles they can filter out. They are particularly useful in environments with airborne particulates that can pose respiratory risks.

Areas of Application::INTRODUCTION

Mercury vapor, acid vapor such as SO2 and dust particulate pollution are considered as significant occupational hazard, particularly in industries such as electronics manufacturing, mining, and laboratories where mercury-containing products are used or produced. Inhalation of these vapors can cause severe health issues, including neurological damage, kidney failure, and respiratory problems. Therefore, protective measures such as respirator cartridges are crucial for safeguarding workers from exposure. The newly developed respirator cartridge features a highly effective filtration system, utilizing modified zeolite as an adsorbent material against mercury, acid vapors and dust particulates. This technology document provides detail about design, functionality, and testing of the cartridge, alongside its compliance with regulatory standards (NIOSH and BIS), and the benefits of using carbon-free adsorbent for enhanced reusability (if required).

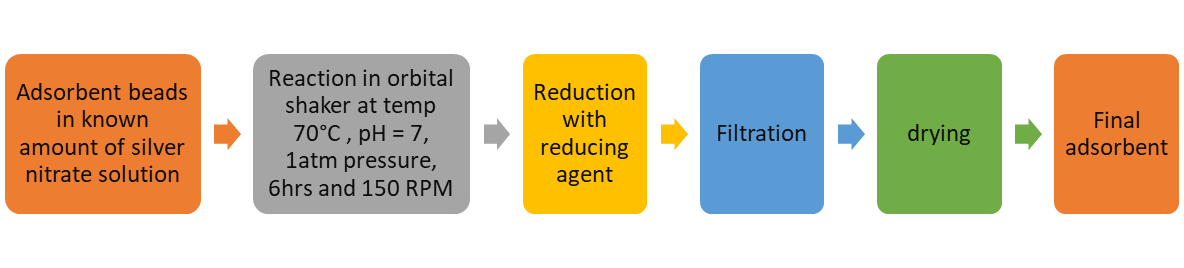

ADSORBENT SYNTHESIS

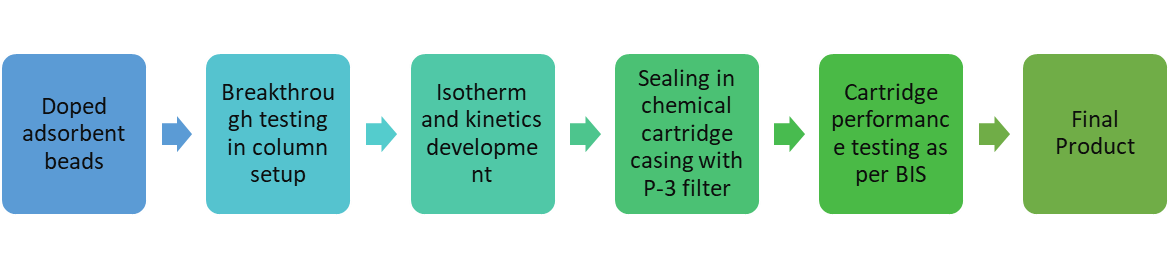

CHEMICAL CARTRIDGE PREPARATION AND TESTING

Mercury Respiratory Cartridges: Mercury is a toxic metal that can be inhaled as vapor, especially in industrial processes such as the manufacture of fluorescent lights, thermometers, or in the mining of gold (where mercury vapor is often released). Mercury vapors are extremely hazardous, and special cartridges designed to filter out these vapors are used.

Areas of Application:Acid Vapors Respiratory Cartridges: Acid vapors, such as SO2, sulfuric acid, hydrochloric acid, and nitric acid etc.

Areas of Application:Particulate Filters: Particulate filters are designed to remove solid particles, such as dust, smoke, and fumes, from the air. These filters are often made from fibrous materials and are classified based on the size of the particles they can filter out. They are particularly useful in environments with airborne particulates that can pose respiratory risks.

Areas of Application:INFRASTRUCTURE REQUIREMENTS

Facilities required

RAW MATERIAL REQUIREMENT

MANPOWER