Ni-based superalloys are preferred choice for high temperature applications requiring good mechanical strength as well as corrosion resistance. Ni-based alloys are broadly categorized into 3 categories: (i) Alloys containing a mainly a high amount of Cr (typically in the range 19 - 33%) and may contain small amounts of Mo (up to about 10%) for strongly oxidizing corrosive media like HNO3 acid solutions, which are commercially available as both solid-solution hardened and age age-hardened alloys; (ii) Alloys containing a high amount of Mo (typically in the range 16 - 25%) with some Cr for strongly reducing media like HCl / HF and H2SO4 acids, which are also commercially available in both solid-solution hardened and age age-hardened alloys; (iii) Alloys containing sufficiently high amounts of both Cr (in the range 16 - 22%) and Mo (in the range 13 - 16%) for multipurpose applications in both types of corrosive media, which only exist in solid-solution hardened condition. Therefore, it has long been desired to commercially exploit age-hardening to impart higher strengths to Ni-Cr-Mo alloys containing about 16 - 22% Cr and about 13 - 16% Mo. Indigenously developed age-hardenable Ni-Cr-Mo-based superalloy overcome strength limitation of solid solution hardened alloy by exhibiting much higher mechanical strength both at room temperature as well as at elevated temperatures upto about 750°C. The alloy can be easily tuned to meet the desired mechanical properties in different applications by adjusting the solutes concentration within a specific range during melting. The new alloy overcome shortcoming of Alloy 625 which get embrittle due to the formation of deleterious delta phase during service life. Its indigenously developed nature promotes self-reliance and reduces dependence on costly imports. Moreover, this technology offer showcases India's prowess in research and innovation, offering a tool that can contribute significantly in alloy and metal industries.

The newly developed alloy has been granted Indian patent vide patent no. 521226 on March 7th, 2024.

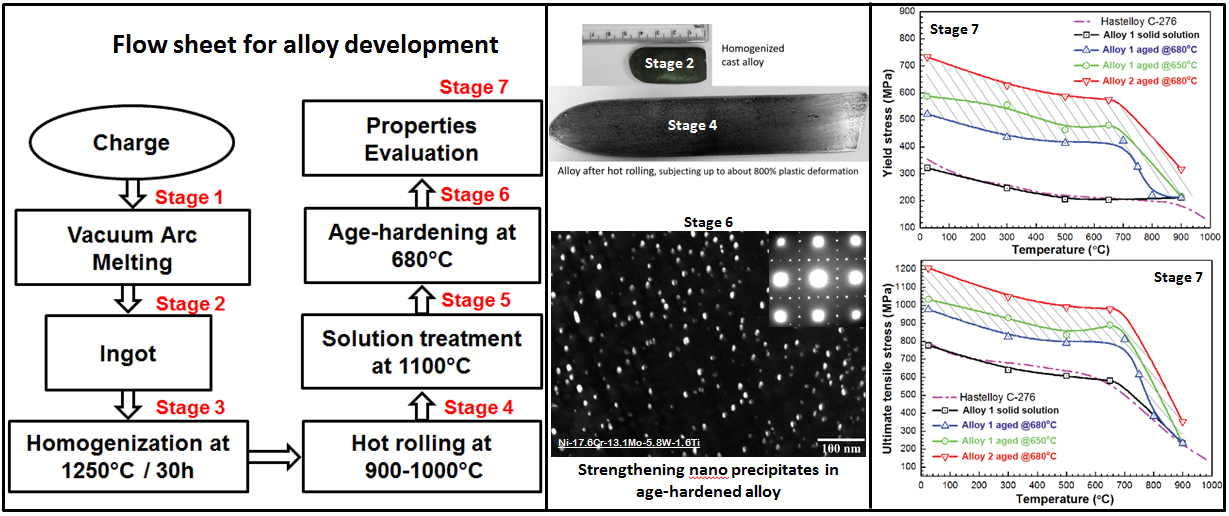

Indigenously developed age-hardenable Ni-Cr-Mo-based superalloy (IAHNBS) overcome strength limitation of solid solution hardened alloy by exhibiting much higher mechanical strength both at room temperature as well as at elevated temperatures upto about 750°C. The alloy can be easily tuned to meet the desired mechanical properties in different applications by adjusting the solutes concentration within a specific range during melting. Its indigenously developed nature promotes self-reliance and reduces dependence on costly imports. Moreover, this technology offer showcases India's prowess in research and innovation, offering a tool that can contribute significantly in alloy and metal industries.

Ni-based superalloys are preferred choice for high temperature applications requiring good mechanical strength as well as corrosion resistance. Ni-based alloys are broadly categorized into 3 categories: (i) Alloys containing a mainly a high amount of Cr (typically in the range 19 - 33%) and may contain small amounts of Mo (up to about 10 %) for strongly oxidizing corrosive media like HNO3 acid solutions, which are commercially available as both solid-solution hardened and age age-hardened alloys; (ii) Alloys containing a high amount of Mo (typically in the range 16 - 25%) with some Cr for strongly reducing media like HCl / HF and H2SO4 acids, which are also commercially available in both solid-solution hardened and age age-hardened alloys; (iii) Alloys containing sufficiently high amounts of both Cr (in the range 16 - 22%) and Mo (in the range 13 - 16%) for multipurpose applications in both types of corrosive media, which only exist in solid-solution hardened condition. Therefore, it has long been desired to commercially exploit age-hardening to impart higher strengths to Ni-Cr-Mo alloys containing about 16 - 22 %Cr and about 13 - 16 %Mo. Indigenously developed age-hardenable Ni-Cr-Mo-based superalloy overcome strength limitation of solid solution hardened alloy by exhibiting much higher mechanical strength both at room temperature as well as at elevated temperatures upto about 750°. The alloy can be easily tuned to meet the desired mechanical properties in different applications by adjusting the solutes concentration within a specific range during melting. Its indigenously developed nature promotes self-reliance and reduces dependence on costly imports. Moreover, this technology offer showcases India's prowess in research and innovation, offering a tool that can contribute significantly in alloy and metal .

Potential application areas of new precipitate strengthened alloy are:

The age-hardenable property in Ni-Cr-Mo based alloys have has been induced by suitable combination of Cr, Mo, W and Ti solutes to stabilizes coherent nano-sized precipitates of γ" phase with a Ni3(Cr,Mo,Ti,W) stoichiometry. The age-hardening strength at elevated temperatures up to 750 °C was achieved by high thermal stability of these precipitates up to about 800°C.