ELECTRONICS & INSTRUMENTATION GROUP

CONTROL INSTRUMENTATION DIVISION

Mr. P. K. KAVALAN

Head of Division

- :

+91 22 25595194

- : webmaster@barc.gov.in

- : www.barc.gov.in

- :

Control Instrumentation Division Office

RCnD Building,

BARC, Trombay,

Mumbai-400085

India

Mandate

Applied research for state of the art instrumentation, control and monitoring systems of nuclear power plants, nuclear fuel cycle facilities and strategic applications.

Highlights

Technologies Developed

Show Cases

It allows accurate time-synchronization of C&I systems using NTP protocol [deployed at ITS lab in RCnD and in Seismology sensor network]

Computer based real time engineering simulator for dynamic response analysis, verification & validation of control algorithms and hardware-in-loop testing of computer based C&I systems [developed as part of Integrated test station (ITS) at RCnD]

Commissioning of RRS, AAS & COIS Systems at Apsara

Integrated testing of Reactor Regulating System (RRS), Alarm Annunciation System (AAS) & Computerised Operator Information System (COIS) at RCnD before dispatch to site

Industrial strength PLC with safety & security features meeting all C&I needs in DAE to meet diverse needs of functionality, performance, safety, security, size, distribution and reliability/availability.

Inauguration of Secure PLC Platform - Integrated Test Facility

Third MoU between BARC and Indian Oil Corporation

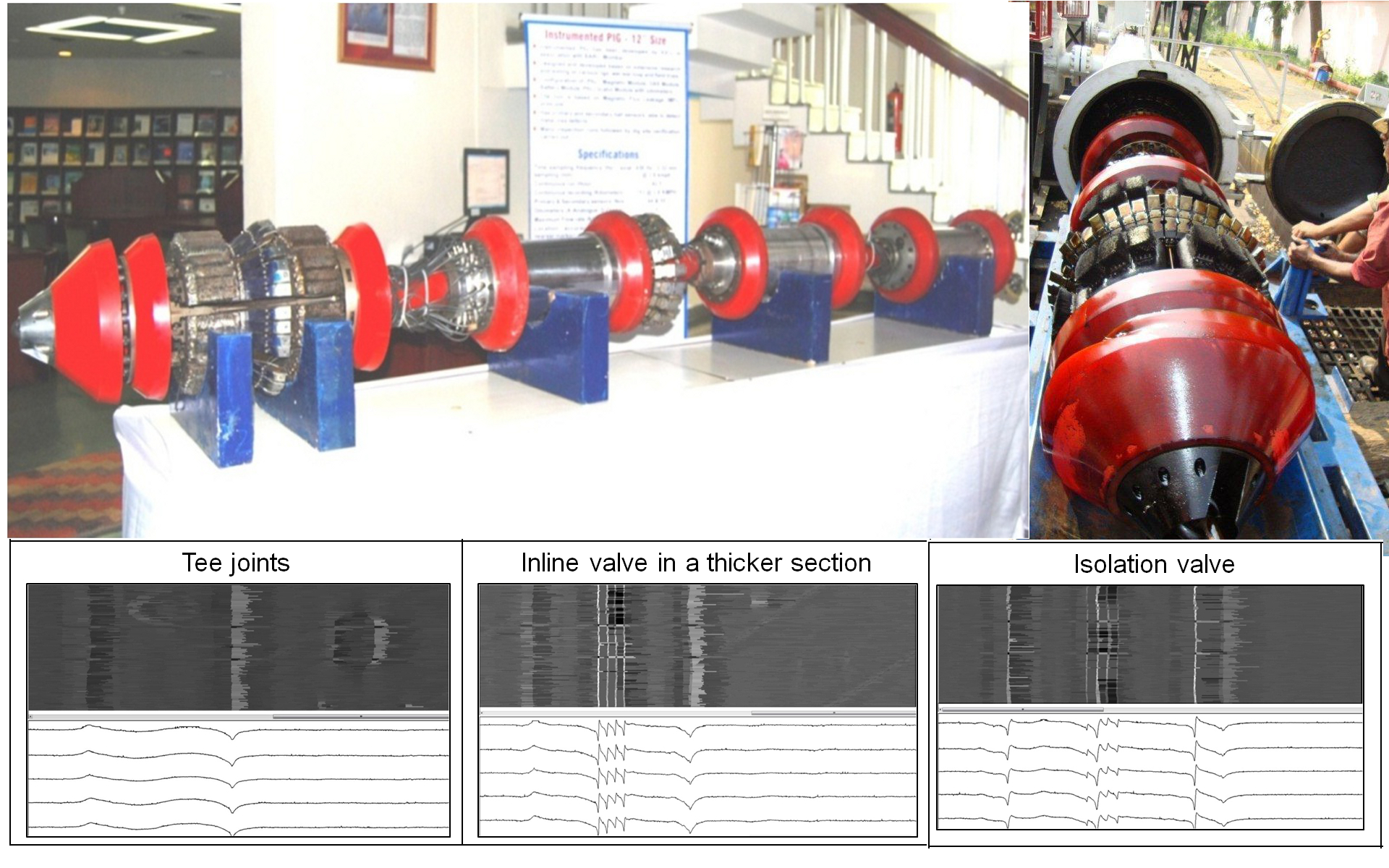

An inspection tool with its signal processing software showing typical pipe features

Inspection run at fire water pipeline at R&D Center, Tarapur