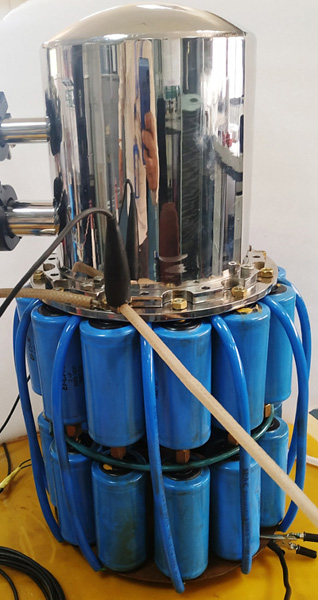

The nanoparticle generator is portable and operates with a power supply of 500Watts only and with single phase 230 volts supply. Because of the portability the agglomeration of nanoparticles due to transport can be drastically minimized. In this way consumption of the nanoparticles can be achieved before they agglomerate. Additionally, almost all the metals can be fed as raw material. The device can be operated by one person only and as per high voltage safety requirement another person can supervise the production.

The system generates metal Nano-powder by electrically blasting optimized metal wire which is fed repetitively and in time control sequence. All the components are available in Indian market so quick maintenance of the system during operation cycle is possible.

The system generates metal Nano powder by electrically blasting optimized metal wire which is fed repetitively and in time control sequence. All the components are available in Indian market so quick maintenance of the system during operation cycle is possible.

The system generates metal Nano-powder by electrically blasting optimized metal wire which is fed repetitively and in time control sequence. All the components are available in Indian market so quick maintenance of the system during operation cycle is possible.

The nanoparticle generator is portable and operates with a power supply of 500Watts only and with single phase 230 volts supply. Because of the portability the agglomeration of nanoparticles due to transport can be drastically minimized. In this way consumption of the nanoparticles can be achieved before they agglomerate. Additionally, almost all the metals can be fed as raw material. The device can be operated by one person only and as per high voltage safety requirement another person can supervise the production.

FACILITIES REQUIRED

For commercial production of the Nano-particle generator one requires a fabrication facility support, a technician of electrical diploma holder to assemble the electrical components. All the components are available in the local Indian market so maintenance can also be easily. Multiplication of the device by making in numbers is also possible to expedite the production process for nanoparticles. Single operating person can operate many devices as they are automatic controlled. High voltage safety demands the supervisor also.