Preparation of Composite Polyamide Reverse Osmosis (RO) membrane

for Brackish Water Desalination

Reverse osmosis (RO) is an efficient desalination technology for providing safe drinking water from brackish and sea water. Brackish water desalination is very common nowadays as most of the surface water available is brackish water. With proper collection and utilization, the reject stream can also be beneficially utilized.

Membrane is the key component of the desalination process. BARC is engaged in the research and development of membrane preparation, assembling in different configurations and applications in various fields. Earlier BARC has developed and transferred the technologies for UF membranes. Technology for rolling of these membranes in spiral module has also been transferred. Present technology is developed for thin film based composite polyamide membranes and prototype 2512 spiral module. These membranes are capable of removing 90% salinity from brackish water (~feed concentration upto 3000 ppm). Using the developed technology, commercial size flat sheet membranes can also be made.

Specifications of 2512 Brackish Water Reverse Osmosis (BWRO)

Sr. No. |

Item | Description |

1 |

Diameter | 2.5 inches (6.25 cm) |

2 |

Length | 12 inches (30.0 cm) |

3 |

Membrane type | Thin-film composite (TFC) BWRO |

4 |

Module configuration | Spiral wound |

5 |

Recovery (max) % | Up to 60% |

6 |

Feed flow rate (max) LPM | 10 -14 lpm |

7 |

Operating pressure (max) bar | 10 -15 bar (depending on feed salinity / flow rate) |

8 |

Feed salinity (max) ppm | 500 - 5000 ppm of NaCl |

9 |

Typical performance | ~ 450 - 500 LMD flux with ~90-94% NaCl separation |

Advantages

- Process is capable of removing dissolved salt to a tolerant level along with contaminant like iron and microbiological contamination with high level of reproducibility from brackish water with upto 3000 ppm salinity.

- Membrane prepared in this process can be used from small units suitable for domestic level to bigger industrial application.

Applications

- This technology can be applied for desalination of brackish water, water reuse (in pharma /biotech, waste water, electrocoating, food and beverage industries) and radioactive waste treatment.

- The TFC membranes in spiral module are capable of removing 90% salinity from brackish water (~feed concentration upto 3000 ppm). There is a potential to use these units for domestic desalination systems.

Process

The technology for Preparation of Composite Polyamide Reverse Osmosis (RO) membrane for Brackish Water Desalination involves various steps:

- Preparation of casting solution using selected polymer.

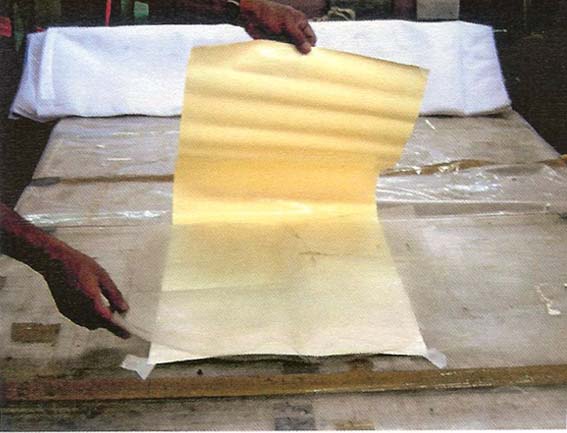

- Preparation of support membrane using casting machine.

- Thin film coating of Polyamide over support membrane using prepared reagents.

- Assembling of TFC membranes in spiral module form.

Raw Materials

Most of the raw materials are simple commercial grade chemicals and are available in bulk in local market. Nonwoven fabric and Polyethylene imine are imported items but local suppliers are available.

Infrastructure

The preparation of support membrane part require dust free environment with proper humidity control. The coating part of the process needs proper exhaust to discharge hexane vapor but in same time the reagent tray should be fully covered to minimize hexane loss. In addition, it requires a small laboratory with few common types of equipment like mechanical shaker, analytical balance, conductivity meter, pH meter, and common glasswares.

Manpower

The manpower requirements depend on the capacity and the extent of automation. However, for manual making of about 50 numbers of 2512 elements per month (including support membrane and composite polyamide membrane preparation) the manpower required are: 1 chemist, 2 skilled lab-technicians and 2 semi-skilled workers.