Production of Intumescent Rigid Polyurethane Foam

INTRODUCTION

The technology offers process for Production of Polyurethane Foam (PUF) including Preparation, Production and Testing of Base Polyols (Grade PD & AM), Isocyanate Component and Polyester Polyol.

PROPERTIES OF RIGID POLYURETHANE FOAM

- To produce an intumescent char on burning to meet furnace testing condition of ASTM E2230

- To have partial open cell structure with the ability to absorb energy on impact from 9m without splintering as per IAEA Regulation

- To maintain a minimum Heat Release Rate (HRR) to withstand sustained temperature of 8000C for 30 minutes

APPLICATION

- The polyurethane foam is suitable for shock and heat shield for transportation packages of radioactive/other materials weighing upto 100 kgs.

PROCESS

The process for production of Polyurethane Foam (PUF) includes production and testing of Base Polyols (Grade PD & AM) and subsequent formulation with catalyst and surfactants. The isocyanate component mixed alongwith the formulated polyester polyols is used for production of Rigid Polyurethane Foam.

The base polyol are produced by the esterification of polyhydric alcohols and acid where the reaction is carried out in jacketed stainless steel vessel with distillation condenser and vacuum arrangement.

RAW MATERIALS

- Diethylene Glycol

- Phthalic Anhydride

- Nonyl Phenol

- Soyabeen Oil

- Diethanol Amine

- Formaldehyde

- Polymeric MDI (Methane Di-isocyanide)

- Ammonium Polyphosphate

Raw materials are easily available in local market.

INFRASTRUCTURE

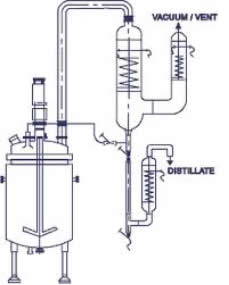

Schematic arrangement is given in diagram

The production of base polyester polyols and their subsequent formulation requires a regular arrangement of a esterification reactor with condenser, hot oil heating and vacuum arrangement.

Approximate area requirement would be 1000 m2 with industrial license for the production of Synthetic Polyester Polyols or resins.

Equipment required:

- Esterification Reaction Vessel with water cooled condenser

- Vacuum pump with collection vessel.

- Thermic Fluid Boiler.

- Blender vessel with gate agitator.

MANPOWER REQUIRED

- Manager – Production - 1 nos.

- Chemist - B.Sc. - 1 nos.

- Skilled Worker - 2 nos.

- Semi-Skilled Worker - 3 nos.