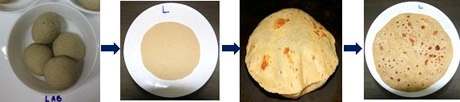

In India, wheat flour is used for making many major staple food items like chapati. However, gluten - a protein complex - present in wheat, barley and rye triggers an unwanted immune response in certain genetically predisposed individuals causing Celiac Disease (CD). A study conducted by Indian Task Force on Celiac Disease (2009) constituted by ICMR (Indian Council of Medical Research showed an increase in the prevalence of CD. ICMR advised Gluten free diet for management of CD. In India, the market size of gluten free products is estimated to be USD 120 million in 2020. (Source: Institute of Agribusiness Management, Bikaner, India). Also, consumption of multigrain foods in general population as a healthy lifestyle is growing due to the increase in the scientific evidence. In 2015, sales of overall health and wellness food products segment Rs. 10,000 crores. Out of which, Rs. 1250 crores were from multigrain atta segment (source: the economic times; Sep 05,2016). With increase in CD and demand for multi grain foods, BARC has developed a Gluten free (GF) premix using multigrain and radiation processed dietary fibre. This GF premixis low in price, better sensory attributes, high in soluble fibre and has a protein content equivalent to regular wheat flour.

BARC has developed a Gluten Free premix by combining various multigrain flours and radiation processed (RP) dietary fiber. Multigrains were judicially selected not only for better nutritional qualities but also for the bringing the price low. With increasing scientific evidences, demand for multigrain and high fiber food items is growing exponentially. Multigrain used in the developed premix is not only limited for special (=medical) dietary purposes but also for healthy individuals. Moreover, addition of RP dietary fiber not only improved total soluble fiber content but also sensory characteristics of the final product.

ICMR (Indian Council of Medical Research) declared gluten Free (GF) diet as a cornerstone for management of celiac disease (CD). Gluten ― a protein complex, which is present in wheat, barley and ryetriggers an unwanted immune response in certain genetically predisposed individuals causing CD. In India, wheat flour is used for making many major staple food items like chapati. Developing a gluten free premix for CD is challenging. Although, many GF premixes are available in market they are either costlier or low in its sensory parameters. So, BARC has developed a GF premix by combining various multigrain flours and radiation processed (RP) dietary fiber. Multigrains were judicially selected not only for better nutritional qualities but also for the bringing the price low. Multigrain used in the developed premix is not only limited for special (=medical) dietary purposes but also for healthy individuals. Addition of RP dietary fiber improved the sensory characteristics of the product.

RAW MATERIALS

EQUIPMENTS

SPACE

POWER

MANPOWER