MAGNESIUM-GALLIUM ALLOY FOR THE SYNTHESIS OF TRIALKYLGALLIUM COMPOUNDS

Introduction :

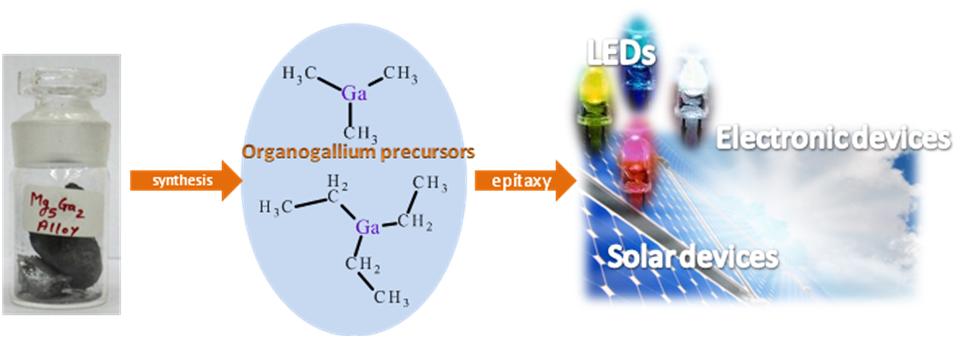

The increasing demand of gallium based materials (e.g. GaAs, GaP, GaN, etc) for micro-electronic devices (e.g. optoelectronic devices, solar panels) has been a driving force for the preparation of organogallium compounds in a convenient manner.

The special stoichiometric magnesium-gallium alloys are versatile reagents used for the synthesis of a range of organogallium compounds. The latter find application in organometallic chemistry, catalysis and in materials science for gallium based semiconductors of gallium based semiconductor materials (e.g. GaAs, GaN, GaP, GaSb, InGaAs, InGaN, AlGaInP, InGaP and AlInGaNP) via metalorganic vapour phase epitaxy (MOVPE).

With special emphasis of the Government of India on setting semiconductor device manufacturing firms in India, the demand for indigenously sourced raw materials is expected to rise.

Specification :

- Stoichimetric ratio of magnesium and gallium are heated together to form an alloy.

- Grey lustrous solid, which can be ground to powder during the synthesis of organometallic compounds.ith special emphasis of the Government of India on setting semiconductor device manufacturing firms in India, the demand for indigenously sourced raw materials is expected to rise.

Salient features :

- Gallium magnesium alloy is easy to handle and can be stored in ambient conditions.

- Use of hygroscopic and expensive chemicals like GaCl3 and MeLi or toxic R2Hg can be avoided.

- Makes the synthetic route simpler.

- Results in higher yields and low levels of trace metal impurities.

Application :

Special stoichiometric magnesium-gallium alloys are versatile reagents used for the synthesis of a range of organogallium compounds.

The latter find application in organometallic chemistry, catalysis and in materials science for gallium based semiconductors of gallium based semiconductor materials (e.g. GaAs, GaN, GaP, GaSb, InGaAs, InGaN, AlGaInP, InGaP and AlInGaNP) via metalorganic vapour phase epitaxy (MOVPE) which are used in fabrication of optoelectronic, microelectronic devices and solar panels.

Infrastructure :

A chemical laboratory having a Induction Heater (12.5 kW, 400 kHz), a stainless steel work table, is required with an area of 10ft x 15 ft with proper ventilation and exhaust, is sufficient for Ga-Mg alloy synthetic setup.

Raw Materials :

The raw materials are easily available in local market.

Manpower

Two chemists (B.Sc. in Chemistry) & One electrician (for maintaining electrical equipment) are required for the production.