Hydrogen Sulphide Sensor with Monitor (Model: TPD-BARC 1050)

H2S Sensor with Monitor (Model: TPD-BARC 1050)

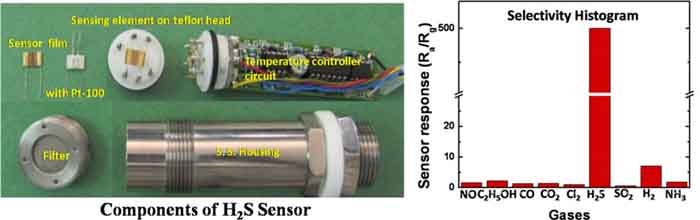

H2S is one of the highly toxic and flammable gases, which is widely used in various industrial applications. Its long-term (8 h) and short-term (10 minutes) exposure limits are respectively, 10 and 15 ppm. The H2S Sensor with Monitor (Model: TPD-BARC 1050) detects H2S using a chemiresistive element, which is highly sensitive, selective to H2S, and stable for more than 2 years. It comprises of a “Sensor Head” and a “Digital Monitor”.

- Sensor Head : The sensor head consists of a sensing element, heater and temperature controller circuit encased in stainless steel housing. The active element is SnO2:CuO thin film mounted on a heater. The best response for H2S gas is obtained in the temperature range of 170 -190°C.

- Digital Monitor : It consists of a Data Acquisition & Control Board, and touch screen based Human-machine interface (HMI) module. The sensor output i.e. the change in resistance as a function of concentration, is provided to the monitor capable of displaying the gas concentration in ppm. The monitor has provision for programmable alarm set points, touch switch to change between Normal and Calibration Mode and store Historical Logs (installation date, calibration date, fault detail etc). Default alarms have been set at 10 and 50 ppm.

WORKING PRINCIPLE

The sensor works on the principle of change in electrical resistance upon a chemical interaction with H2S. This change is calibrated and displayed directly on a digital monitor as H2S concentration in ppm.

The sensor element is a SnO2: CuO thin film, in which the p-type CuO and n-type SnO2 form random p-n junctions, leading to a very high resistance in air (of the order of MΩ). On H2S exposure, CuO converts to metallic CuS which results in a drastic decrease in electrical resistance. In the presence of air, CuS gets converted back to CuO and the original state is restored. As both the chemical reactions are unique to H2S, therefore these sensors exhibit negligible response towards other gases.

SPECIFICATIONS

|

: 10 - 50 ppm |

|

: 170 -190°C. |

|

: 3 - 5 min. |

|

: < 15 min. |

|

: > 500 |

|

: Excellent |

|

: ~ 2 years |

APPLICATIONS

- Heavy water plants

- Sewage treatment plants

- Oil and gas industries

- Pulp and paper making industries

- Chemical industries

- Chemistry laboratories

REQUIREMENTS FOR SENSOR FABRICATION

A. Sensor head

- Cutting machine for Alumina substrates

- Ultrasonicator for cleaning substrate and source materials

- Thermal evaporation system for SnO2:CuO thin film deposition

- Furnace for annealing

- Temperature control circuit with teflon head

- Stainless steel housing

- Work bench for assembly

B. Digital monitor

- Human Machine Interface (HMI) unit for display

- Printed circuit board and components

- Enclosure, connector cable and 24 V power supply

C. Sensor calibration

- Calibration chamber

- Gas canisters and syringes

D. Space

- A room of 5×6 m2 floor area is needed to accommodate above mentioned facilities

MANPOWER REQUIREMENT

2 Numbers

- 1 person with bachelor degree in Physics/Chemistry

- 1 person with diploma in Electrical/Electronics