ChemoMechanical Magneto Rheological

Finishing (CMMRF) Machine

INTRODUCTION

Chemo-mechanical magneto-rheological finishing (CMMRF) is a hybrid finishing process of CMP (chemo-mechanical polishing) & MRF (magnetorheological finishing). CMMRF machine has been developed to generating atomistic or nanometric surface on various engineering materials. It comprises Controller, 3-axis CNC-based machine, slurry system, finishing head, and working table.

ADVANTAGES

The process is flexible finishing process, which would be employed to finish flat surfaces in order of nano to sub-nano metric level. Finishing pad life is endless (there is no need to use conditioner on the pad). And chemical aspect of finishing introduces atomic level of surface finish (less than 1nm) and very high finishing rate as compared to other existing process.

APPLICATIONS

General optics, LASER Optics, Soft X-ray Optics, Hard X-ray Optics, High speed rotor, Micro-fluidic devices, Micro-tools, Metrological-probes, Micro-fabrication platform for R&D, Dies & molds, MEMS & NEMS fabrication, IC chip & microelectronics fabrication, LINAC RF Cavity, Hip joints, Knee joints, Stents.

PRINCIPLE

During material removal in CMMRF process, two actions simultaneously take place, namely, chemical reaction and magnetic assisted mechanical abrasion.

Chemical reaction of silicon with cerium oxide, deionised water, colloidal silica, hydroxyl ions and oxygen are used to convert silicon and silicon dioxide into chemically

passivated layer (soft complexes of silicon). The chemically passivated (soft) layers are then easily swept away by magnetically controlled mechanical action. To

comprehend mechanism of CMMRF process, Prestonís model of CMP process and rheological behaviour of MRF phenomena are described as follows;

Preston (1927) has modeled of CMP process: → Polishing rate (PR) = KPV

MRP fluidís model is assumed by consideration of its rheological behaviour similar to the Bingham plastic fluid: → Abrading Shear stress = t = to + μ(V / g)

Where K = constant of chemical reaction; P = polishing pressure on abrasive; V = polishing velocity; g = working gap; t = shear stress on the MRP fluid at finishing

plane; to = threshold shear strength of MRP fluid; μ = dynamic viscosity of MRP fluid.

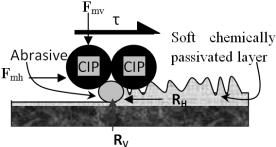

Fig. 1 a)Mechanism of material removal of CMMRF

b)Free body diagram of active abrasive

Since polishing pad (brush) is generated by MRP fluid, pressure (P) is being generated because of magnetorheological shear stress (τ) action. This conversion of the shear stress into polishing pressure can be comprehended by fluid hydrodynamics. Figure 1 shows combined effect of CMP and MRF, whereas, chemical passivation and subsequent magnetic assisted mechanical abrasion is also presented.

EQUIPMENTS

The CMMRF system includes Precision Orientation Table, Polishing head, and Slurry system with controller. This system should be mounted in any 3-axis machine to perform finishing operation.

INFRASTRUCTURE

Precision Machining, Metrology, Fabrication, Electronic fabrication & testing and Assembly facility.

MANPOWER

This is novel work in field of advanced manufacturing technology. Development of this facility needs people whose areas of expertise belong to precision machining & assembly, fluid circulatory system, and ‘electronics-instrumentation & system integration’.

For details contact :

†††

BHABHA ATOMIC RESEARCH CENTRE,

TROMBAY, MUMBAI - 400 085

Fax : 091-022-25505151

Email : technology@barc.gov.in