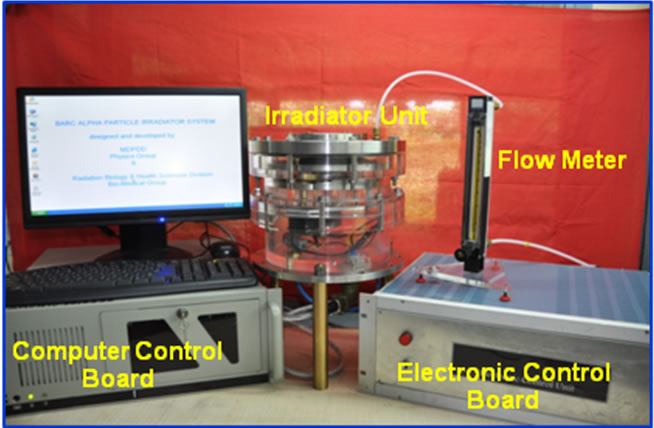

AUTOMATED ALPHA PARTICLE IRRADIATOR- BIOALPHA

BIOALPHA is the first indigenous computer controlled Alpha Particle Irradiator for alpha irradiation of biological/non-biological samples. A special assembly is required for alpha irradiation of biological samples due to very low range of alpha travel in air and samples need to be irradiated only at atmospheric/physiological conditions.

A controlled, collimated and uniform alpha irradiation can be achieved using Bio-alpha due to its innovative design. The system is designed to irradiate adherent mammalian cell cultures. However, in principle, the system can be used to irradiate any material/samples (biological/non-biological); placed in a layer (thickness range should be below the penetration of alpha particles in the sample); with defined time/dose of alpha radiation

SALIENT FEATURES

- Computer controlled automated mechanical system

- Uniform and collimated exposure of alpha radiation to cells in culture condition

- Variable speed of source and collimator movement with independent control

- Auto and Manual mode of operation

- 241Am source housed inside lucite chamber, which is flushed with helium to minimize the attenuation of loss of alpha energy

- High speed shutter

- High-precision electronic shutter control through computer to irradiate samples 1 sec to 99 min

- Store/save of experimental information like user name, sample details, exposure time, source/collimator speed etc.

- Exit window: 1.5 µm thick Mylar sheet

- Collimator: Aluminum sheet perforated (1 mm diameter)

SPECIFICATIONS

Collimator

- Honeycomb structure, 68mm x 55mm, 3mm thick with holes (1 mm diameter) at regular intervals and 2 mm pitch

- Material : Aluminum or SS if machined or any Plastic suitable for 3D printing

- Closed in 'Off' position and when not required.

- Speed: 1/30 seconds or higher.

- Diameter of Aperture: 50-65 mm.

- Shutter blades: ~4-6 Nos.

- Solenoid coil: 12 or 24 V DC.

- It should remain open for the time set in the controller.

- Shutter should not contain any glass or lens.

- Power supply for Shutter - Input supply: 230 V AC,50 Hz , Output supply: 12 or 24 V DC

INFRASTRUCTURE REQUIRED

- Lathe with Centre Height: 250mm

- Milling Machine: XYZ Travel minimum 400x400x400mm

- Drilling Machine: 12mm drill size

- Soldering Iron

- Helium Leak Detector

- Space Required: Space occupied by instrument with stand (L x W x H): 1000x1000X2000 (mm)

- Power supply: 230 V, 10 A DC

- Manpower: 2 Turner, 2 Fitter, 1 Miller, 1 Electronics Technican

Note: Procurement of source and requisite permissions for the same will be user’s responsibility.

FIELD OF APPLICATION

- High LET Radiation Biology for mammalian cells, microbes and plant cells. A thin section of tissue or organisms of very low thickness could be irradiated using the system with proper optimizing irradiation/incubation conditions and dosimetry

- Radiation Induced Bystander Effect studies

- Low dose/fluence Radiation Biology