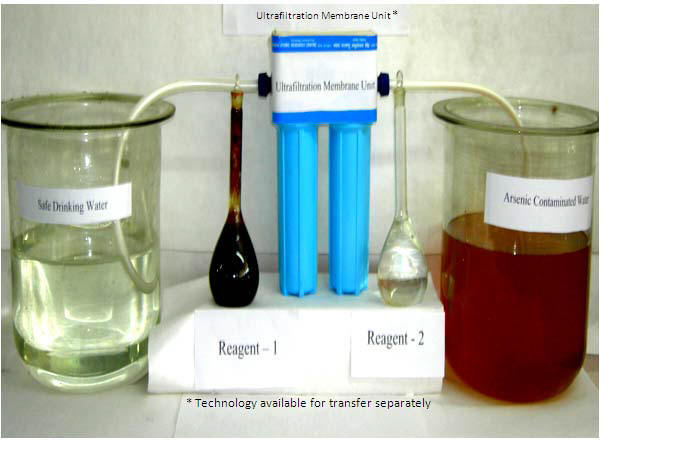

ARSENIC REMOVAL FROM DRINKING WATER

Ultrafiltration Membrane

Assisted Process

INTRODUCTION

Arsenic (As) is known to be a very toxic element and a carcinogen to

human. Even a trace amount of arsenic can be harmful to human health.

The World Health Organizations (WHOs) current provisional guideline for

arsenic in drinking water is 10 ppb. In India, states like Uttar

Pradesh, Bihar, Jharkhnad, West Bengal, Assam, Manipur, mainly in

Ganga-Meghna-Brahmaputra (GMB) plain covering an area of about 569749 sq

km with a population of over 500 million have reported serious illnesses

due to presence of arsenic.

The arsenic removal from drinking

water by physicochemical process provides process for decontamination of

water with respect to arsenic. BARC developed know how of

ultrafiltration (UF) based membrane technology for water decontamination

with respect to microbiological contamination at both

domestic and

community scale is available for transfer separately. The present

technology is a novel Ultrafiltration (UF) membrane assisted

physicochemical process for removal of arsenic from ground/surface water

to make the water safe for drinking.

Salient features

• Simple and rapid

•

Adoptable at both domestic and community level

• Capability of high

decontamination - Product water not only free from arsenic but also free

from secondary contaminants like iron,

manganese and microorganisms.

• Can operate without

electricity

• No specific requirement for waste disposal

• Cost

effective

Applications

• Removal of arsenic

from ground/surface water to provide safe drinking water free from

primary contaminant like arsenic as well as

secondary contaminants like iron and microorganisms.

• Technology can be adopted at both domestic and community level

Process

UF membrane assisted

physicochemical process/device is capable of removing arsenic

contamination from ground/surface water for drinking purposes from a

feed concentration of 500 ppb or more to less than 10 ppb (which is the

desirable limit set by BIS). The entire process involves two steps: 1)

Sorption of arsenic species on the in situ generated sorbent by simple

addition of two reagents. 2) Filtration of arsenic containing sludge

using UF membrane device based on the technology developed by BARC. The

two reagents required for the first step are to be prepared using the

procedure given in the technology transfer document. The details of the

device required for the second step is available in the form of

technology with BARC and can be taken separately. These devices are also

available with several licensees of BARC in the form of commercial

products.

Raw Materials

All the raw materials required for preparing the reagents for removal of

arsenic are available in the local market.

Infrastructure

The development of arsenic removal kit requires a small laboratory with

few common equipments like weighing balances, exhaust and common

glasswares.

Manpower

One Chemist and one skilled worker would be adequate for the purpose.

Cost Aspects

The cost of raw materials for preparation of reagents sufficient to

treat 1000 liters of arsenic contaminated water (contamination level:

500 ppb) is approximately Rs. 8 /- . The cost of UF membrane device

required for filtration will depend if the filtration unit is directly

purchased from the market or the service provider is manufacturing it by

becoming of licensee of BARC.

For details contact :

BHABHA ATOMIC RESEARCH CENTRE,

TROMBAY, MUMBAI - 400 085

Fax: 091-022-25505151

Email : technology@barc.gov.in